In today’s world, recycling has become a cornerstone of environmental conservation and sustainable business practices. From large-scale industrial operations to small community recycling centers, baling plays a critical role in compacting materials such as cardboard, plastics, and textiles for transport and reuse. Central to this process is the use of baler strapping—also known as banding, twine, string, or binding—which ensures bales are securely tied for efficient handling and storage.

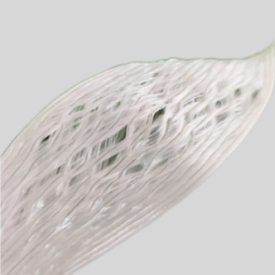

Baler strapping refers to a robust and flexible material designed to tie compressed bales of recyclable materials. It is typically used in conjunction with baling machines, which compress loose recyclables into dense, manageable units. Strapping materials come in various forms, including fiber straps, polypropylene straps, and steel wires, each suited to different applications.

Fiber straps, such as composite straps, are increasingly popular due to their combination of high tensile strength and lightweight design. Unlike steel straps, fiber straps are resistant to rust and safer to handle, making them ideal for securing bales of cardboard, paper, and soft plastics.

Baler strapping is indispensable in industries ranging from manufacturing to waste management. Recycling centers, for instance, rely heavily on strapping to bundle cardboard boxes, plastic containers, and other recyclable materials. In agricultural sectors, baler strapping is also used to tie hay, straw, or silage bales, ensuring they remain intact during transportation.

Plastic and textile manufacturers also benefit from baling processes. Compacting production scraps or defective products reduces waste volume and streamlines recycling efforts. Baler strapping guarantees that these tightly compressed bales remain stable, reducing the risk of material spillage or damage.

The advantages of using high-quality baler strapping are multifold. First and foremost, it enhances the safety of handling compressed bales. Loose or poorly tied bales can pose significant risks during transport, potentially leading to workplace injuries or material losses. High-quality strapping provides a secure grip, ensuring that bales stay intact from the point of compression to their final destination.

Moreover, using the right strapping material can lead to cost savings. Durable and flexible strapping minimizes the likelihood of breakage, reducing the need for frequent replacements. It also optimizes the efficiency of the recycling process by ensuring that bales maintain their compact form, allowing for better use of storage and transport space.

The demand for eco-friendly and sustainable materials has driven innovation in the baler strapping industry. Manufacturers are increasingly focusing on developing recyclable and biodegradable strapping solutions to align with global sustainability goals. For example, some companies now offer strapping made from 100% recycled materials, which can be recycled again after use.

Another trend is the adoption of smart strapping solutions. These involve incorporating RFID tags or QR codes on straps to provide real-time tracking and inventory management. Such innovations not only enhance operational efficiency but also provide valuable data for improving recycling logistics.

BSTSTRAP, a global leader in the production of baler strapping, has been at the forefront of this industry for over 16 years. Specializing in composite straps and fiber strapping, the company offers customized solutions tailored to meet the diverse needs of clients in waste management, manufacturing, and agriculture. With a strong emphasis on quality and innovation, BSTSTRAP’s products are engineered to provide superior performance and durability, making them the go-to choice for securing even the heaviest and most compressed bales.

As global recycling efforts intensify, the role of baler strapping in ensuring efficient and secure waste management cannot be overstated. Whether it's cardboard, plastic, or agricultural produce, reliable strapping solutions are essential for optimizing the recycling process and promoting a more sustainable future. With continued innovation and a focus on environmental responsibility, the baler strapping industry is set to play a pivotal role in shaping the recycling landscape for years to come.